|

|||||||||

|

|

Leopard-2A0-A4 armor protection estimation

by Jaroslaw (Militarysta)

Gun mantled

mask area

Turret

armor left side (the loader)

Turret

armor right side (the tank commander and gunner)

Turret

sides on crew compartment area

Turret

bustle

Turret

roof armor

The hull

frontal armor

The

psychical thickens of the armor summary

The protection of whole tank can be describe in

3 aspects:

It's important to notice that Leopard-2

was developed as child of the many compromises - and some solutions judge now

as bad - where developed in 1970's to achieve better fire power

(placement EMES-15 main sight in gap in frontal armor to simplicity optics

and thermal camera in main sight) or to achieve better susceptibility

to service and repairs - for example huge gun mantled mask was

developed to achieve possibility to replace whole tank gun on battlefield

without removal turret from chassis.

In the breakthrough of the 1980s and

1990s when some solutions in Leopard-2A4 stars to be bad in term of armor

protection (against suspected new Soviet anti-tank weapons) program KWS was

started and deep modernization to 2A5 level was introduced when most

questionable problems whit armor integrity where solved (improvement).

1) Psychical thickness of the tank

armor:

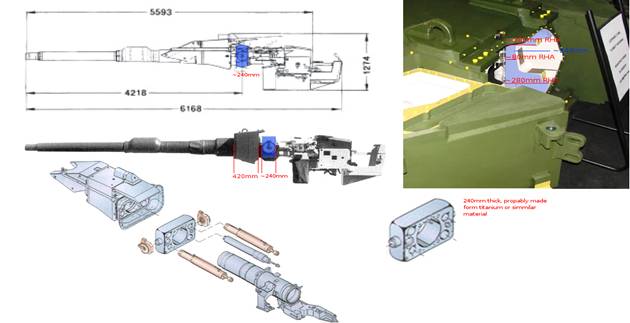

Gun mantled mask area Gun mantled mask in Leopard-2A4 is 420mm

(42cm) thick and it has multilayered build. It's weight is equal 620kg. After

the gun mantled mask is placed gun mounted frame (the wedge in German) made

from thick light alloy metal. Those frame is belted by thick metal

plates which are making roof armor and bottom of the turret. Sides are cover

by thick RHA plates which are making pins to fixed gun and gun mantled mask

in one point in turret.

Whole area looks like this:

In fact whole armor layout in gun mantled mask

area consist:

420mm armor block + 240mm light alloys

mounted frame for gun + around mounted points between 80 and (mostly) ~230mm

RHA metal plates. Thanks for this solution whole gun mantled mask area where

protected well against early 1980s APFSDS and HEAT munitions penetration this

area by 3BM15 or early BK-15 round was rather questionable, and low

possible to achieve. Leopard-2A4 gun mantled mask was immune against BMP-1

main armament 2A28 Grom low pressure gun whit HEAT rounds, and Maliutka ATGM.

Turret armor left side (the loader)

Physical thickness of the loaders turret

part frontal armor is incredible (in the end of the 1970s) 860mm LOS. Armor

back plate (metal plate ending whole special armor cavity) is made from 60mm

RHA plate made from high hardness steel, frontal plate is probably the same

thick. Between them is cavity (circa 740mm) for special armor module. This

special armor module can by quickly replaced by cutting upper (roof) plate

and change whole module. Similar process takes in

Such big thickness was necessary due to

Turret armor right side (the tank commander and

gunner)

The tank commander is protected by 660mm thick

special armor block in front of his face. Now this area (behind EMES-15 main

sight optics block) is consist as weak area but in almost whole 1980s is hard

to agree with such statement 660mm LOS is space bigger then in most

tank's in those era (except M1 Abrams) and should allow (by using more

heavy armor components) to achieve similar to the left side (loaders)

protection.

Thickness of the armor in front of the gunner

position is the same as on the left turret side so 860mm but whit different

layout: the first armor cavity gap for EMES-15 and WBG-X components the

second armor cavity. So whole thickens is close to

Turret sides on crew compartment area

Crew compartment turret sides are

protected by

Turret bustle Whole turret bustle after crew

compartment is protected only by simple RHA armor. This solution was forced

by weight reasons. It's the biggest weak area for whole Leopard-2 tank -and

almost impossible to fixed even now. Partially it's cover by tactics of tank

using front toward enemy, but in exist now non conventional warfare whole

Leopard-2 turret bustle seems to be significant weakness, unable to cover

without Active Protection Systems (like KAZ Drozd, or Trophy or AMAP-ADS).

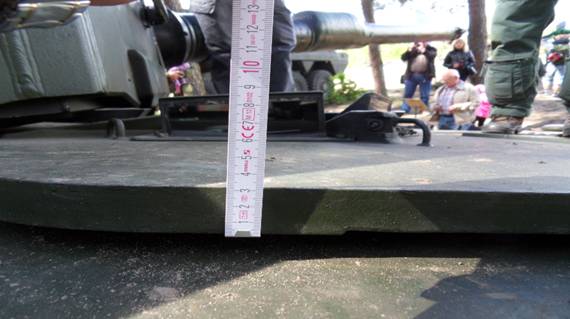

Ammo rack in Leopard-2A4 bustle (whit

blow out plate of course) is cover by circa 80mm thick armor so for 30 degree

it's 160mm thick. Turret bustle rear is cover by only 25mm thick RHA plate:

Turret roof armor:

Leopard-2A4 turret roof armor is

separated on PERI- loaders periscope line. The frontal part of roof is made

by probably (author is not sure)

The hull frontal armor

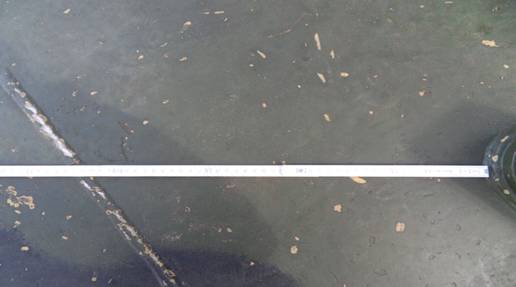

Upper glacis plate is 40mm thick and

slopped at 7 degree (so

The driver hatch is 30mm thick:

and it's construction was imperfect whole hatch

was vulnerable on 30mm gun fire and small AT warhead so in Leopard-2A5

whole construction was totally change. The driver hatch is second biggest

Leopard-2 weakness.

Leopard-2A4 hull sides consist 3 thickness(!).

Driver right arm is protected (near hatch area)

by 80mm thick RHA plate -but only there.

It's important to notice that above

track Leopard-2A4 sides are protected by multi spaced armor consist by:

external 25mm RHA plate circa 580mm thick fuel tank 50mm hull armor.

According to Israeli the Merkava tank

developers 70mm of the fuel is equal to 10mm armor plates. So 580mm fuel act

(vs HEAT warhead) as 80mm armor plate. Such layout was better in 30 degree

conditions and gives probably enough layers and space to stop older RPG-7

grenades.

Under the fuel tank Leopard-2A4 sides

are protected by 50mm hull armor and 12mm light side skirts:

Each module weight more then 110kg, and

consist two 50mm RHA plates separated by air gap.

So protection of sides under track line

is 100mm RHA plates + space + 50mm hull armor.

For 30 degree it's give 200mm plates +

space + 100mm hull armor. What including high hardness plates was enough in

late 1970 to stop most light AT weapons and older gun rounds.

Now such protection is not enough ands

almost all asymmetric warfare leopard-2 modernization consist new much

thicker heavy ballistic skirts for almost whole hull sides.

The

psychical thickens of the armor summary:

Integrity of the amour protection and weak

zones placement for tank for 0-30 degree from longitude axis

In Leopard-2A4 armour integrity is secondary

factor the absolutely priority for developers had firepower, mobility

and susceptibility to service and repairs. Many of the Leopard-2

solutions are given as the example of the weak spots or bad armor integrity.

For the most often noticed flaws we can included:

enormous gun mantled mask

armor block after EMES-15 sight vision block

lack special armor for turret bustle

In fact ONLY the last one example can be

describe as seriously weak spot but only for sides or 15-30 degree from

longitude axis. Leopard-2 developers decide for such solution for weight

reason.

Armor block after main sight EMES-15 optics

block can't be described as weak spot for whole 1980s. Why? Because

660mm LOS thickness is exactly the same value as frontal turret armor most of

1980s tanks:

In T-64A and T-64B frontal turret armor is

maximum 485-

(source: http://btvt.narod.ru/raznoe/bulat-leo2.files/image011.jpg)

it's still smaller value then 660mm armor.

In T-80B case for frontal LOS it's between 560

and 640mm (for 30 degree

I case T-80U turret armor is mostly ~ 600mm LOS

(source: http://btvt.narod.ru/raznoe/bulat-leo2.files/image011.jpg http://btvt.narod.ru/4/bars_leopard/80-1.jpg)

What again is smaller value.

Frontal T-72B armor is between 600 and 750mm and

for 30 degree it's 600-680mm what still is the same value as 660mm LOS in

Leopard-2.

For such reason 660mm thick armor block in

Leopard-2A4 can't be describe as weak spot in compare whit soviet tanks

500-600-

In breakthrough of the 1980s and 1990s when new

ATGMs and APFSDS rounds become available and new, improved soviet tanks

turrets become available (Ob.187, Ob.478BE, etc) it's starts to be clear that

indeed in 1990s those area will be serious flaw. For that reason frontal

armor was completely changed in KWS program, and now left and right armor is

the same in armor thickness (~860mm).

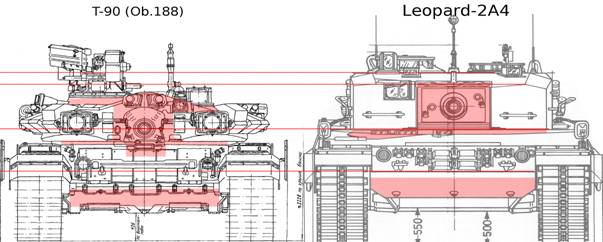

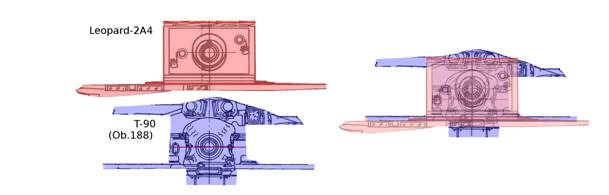

Gun mantled mask in Leopard-2 is 93cm width what

is comparable whit soviet tanks mostly cast gun mounted points and

coaxial MG areas this area in soviet tank is circa 83-86cm width.

So both values are comparable.

For such reasons in whole 1980s and early 1990s

(before much better Ob.478BE and OB.188A1) weak spots for Leopard-2A4 and

most Soviet Tanks where comparable:

and both weak areas can be compare on

one picture:

Of course in compare whit T-80UD

Leopard-2A4 seems to have much worse conditions.

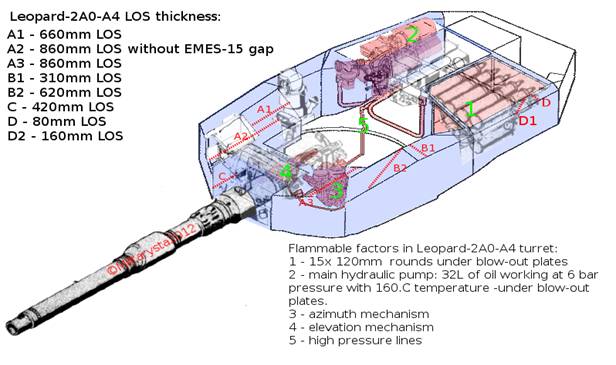

In fact Leopard-2A4 turret can be

compare in both aspects: armor integrity, weak areas, and hazardous factor

(ammunition, oil pumps, etc) on one picture:

Know special armor features and

possibility to protect against KE monitions and CE munitions

In special armor case we don't known details.

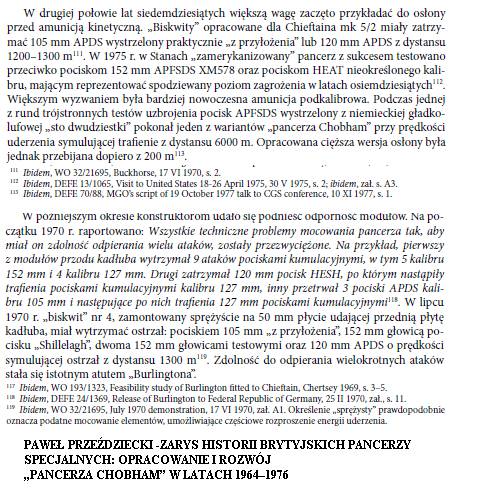

Thanks to Pawel Przezdziecki reseerches in

British armour was build as some kind of

"bulkhead armor" whit space flitted by layers made (those layers)

as sandwich - two thin steel layers and between them non metallic layer

In configuration from at the turn of 1960/1970,

against SC warhead "Burlinghton" was 2-3times better then

monolithic steel armour whit the same mass, and had (Burlinghton

armour-milit.) similar resistance (as those monolithic steel armour ) against

kinetic energy rounds.

The mass efficiency of the new armour variants

(Burlinghton -milit) increased to 1.3-1.5 against KE and do more then 3 against SC warhead (HEAT) This part is about Burlinghton from circa 1978r.

Translate part 1:

This above is last hard data known about

burlington-style armour. In case Leopard-2A4 we can assume or estimate armour

protection.

They are sevral metods to estimate armour

protection, and most of them give simmilar result in two groups of the option

(the best and the worst), avarage between both options give us

sucht values:

For turret for:

860-760-620mm LOS

(turret front, turret front for 30 degree,

turret sides for 30 degree)

vs APFSDS (in mm RHA)

570-510-410mm

vs HEAT (in mm RHA)

910-810-640

hull for 640mm LOS thickness:

circa 500mm vs APFSDS and circa 700vs HEAT

Such values should be compare whit ammunition

level in 1980s:

ammo mark penetration achievable (A) on 2000m, - penetration guaranteed (G) on 2000m

3BM-26: A: 440mm G: ~400mm

and whit typical SC (HEAT) warhead abilities:

9М111М (1983) penetration

As we can see during whole 1980s. Leopard-2A4

armor in theory was good enough protection - at least for turret and hull

front even on circa 1000m distance. For the other hand: Soviet tanks

protected by heavy Kontakt-5 ERA armor was very difficult enemy for western

tanks.

|

|

|||||||

|

|

|